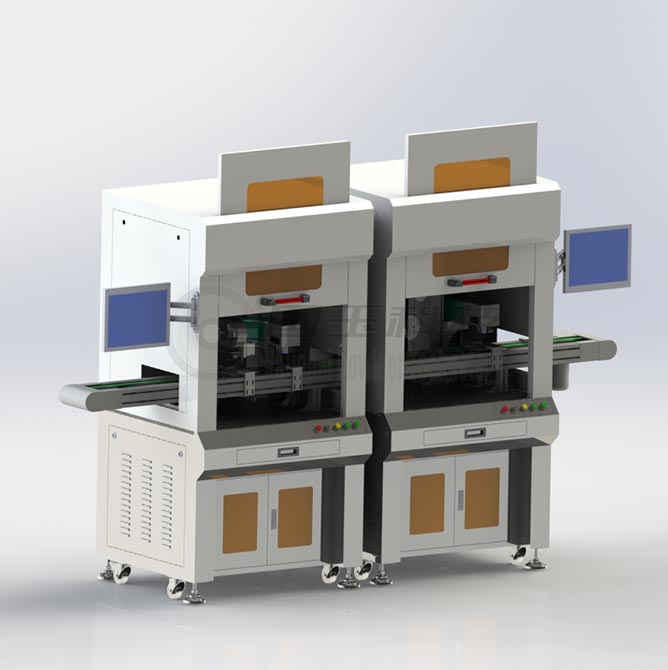

Laser Machine for Glue Removal

Widely used in the internal circuit glue cleaning and removal on the 3C electronic products.

Current location: Home / Product System / Intelligent manufacturing

Widely used in the internal circuit glue cleaning and removal on the 3C electronic products.

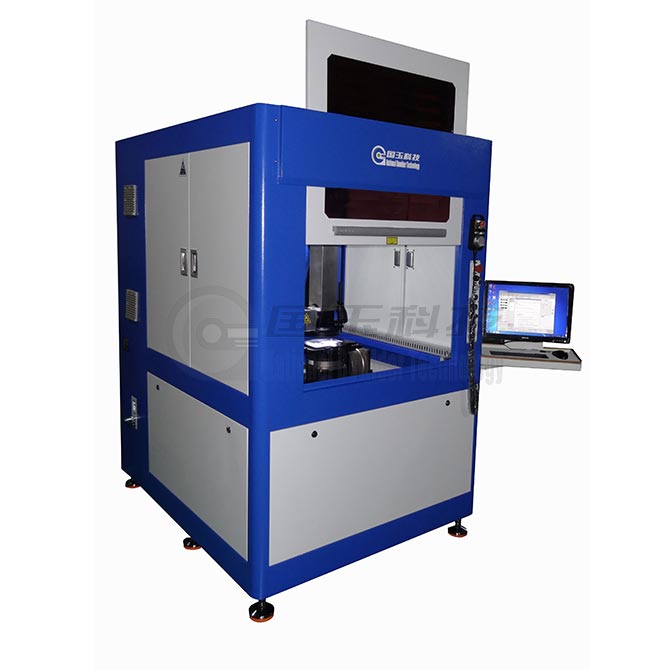

Widely used in the high precision products assembly line, equipped with various functions such as automatic sample loading and unloading, welding, assembling, measurement, testing, which provides all the possible solutions for manufacturing.

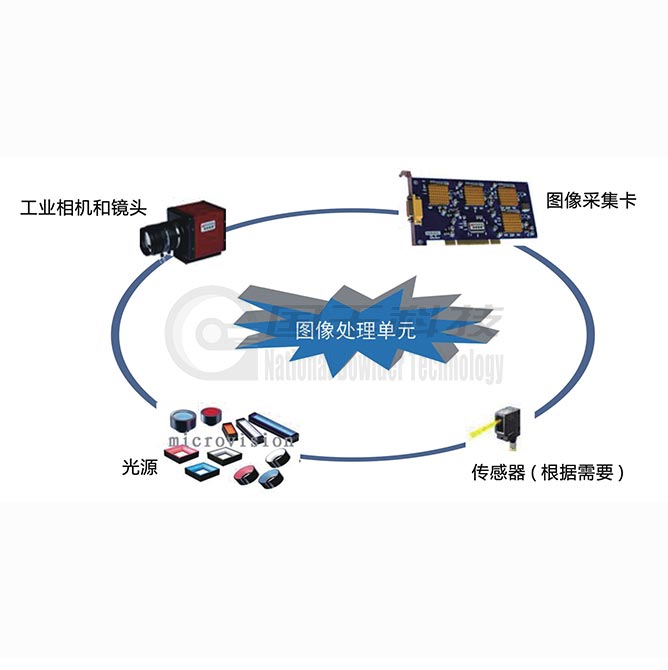

Support different camera’s brand, multiple tasks parallel running, hundreds of algorithm, secondary development and communication mode TCP/IP、RS232、I/O.

Widely used in the sorting, counting and inspection of the SMT resistor reels in less than 1mm thickness and 8mm, 12mm or 16mm width

The visual system developed by NBI can automatically classify the grey level and size of different stains on the surface of the product; It uses the algorithm to divide different types of doping based on different laser processing parameters, thereby blackening the stains to be consistent with the surrounding background color, The chromatic aberration is difficult for the human eye to detect. That is why the repair of anode defects is needed and widely used in the three-dimensional surface inspection and repair of the shells of smart phones, notebooks, tablets, and wearable products.

Widely used on the carton box, shielding bags, sample plate and other external package’s code and tap removal.