Proposals for the Current industrial development

In recent years, smart fast-fashion kitchen utensils and small household appliances have begun to enter our daily lives. Air purifiers, floor cleaning robots, dishwashers… Obviously, the wave of home appliance consumption upgrades is gradually spreading to the field of small home appliances, but the achievements of small smart home appliances are quite impressive, as if they have become the “new favorite” of the home appliance industry.

As the consumable upgrade trend of household appliances gradually spreads to the field of small household appliances, more and more high-end, smart, and healthy small household appliances have become the main driving force for the growth of the household appliance market. There are three types: one is the health and well-being related household appliance. These household appliances are mainly kitchen utensils such as juicers, soymilk maker, rice cookers, etc. This type of household appliance meets our needs of pursuing for a healthy and diversified diet. The second type is small household appliances that rely on the “lazy economy” to succeed. In another word, new products that free our hands, such as dishwashers, floor cleaning robots, and cooking machines, have become standard equipment for many families. The third type is beauty and fitness appliances, humidifiers, cleansing devices, beauty devices, facial massagers and other varieties, which attract many beauty lovers.

According to relevant data, in 2015, the global retail sales of small household appliances exceeded 2 billion units. Among them, small kitchen appliances accounted for 42%, personal care appliances accounted for 25%, and other categories of small appliances accounted for 33%.

Therefore, the current fast fashion and practical kitchen appliances have gradually become the main direction of the industrial development. At the same time, there are five national standards that small home appliances has to be qualified when entering the market, including: Safety Standards, Food-contacting Material Safety, 3C Certification, Minimum Allowable Values of Energy Efficiency, and Energy Efficiency Grade. This requires manufacturers to not only meet the needs of the fast fashion market but also to meet the national quality requirements in all aspects while the products that are quickly introduced to the market. Under these major premises, the requirements for efficiency have been put forward for the product development, small batch production, and mass production of the kitchen appliance industry. The application of laser technology can effectively meet the requirements of the fast-fashion kitchen appliance industry. For example, the use of laser cutting instead of die stamping for small-batch products in the stage of research and development can guarantee the rapid completement of the appearance and structural function verification in the earlier stage. In the mass production stage, the use of robot automatic laser welding instead of traditional manual welding can save cost for replacement and the time to train workers to adapt to the new technology for new products. Moreover, the application of new laser technology can greatly improve the quality of new products, thereby reducing the commodity quality problems after they are launched on the market. Therefore, the laser automated manufacturing process has become an indispensable boost for the development of domestic fast-fashion home appliances.

industrial proposal with laser application

-

The continuous laser pipe cutting equipment developed by NBI is a laser processing equipment that can be put into continuous production. It can be directly connected to the pipe marker in order to achieve continuous and non-stop cutting. In addition, the cutting system can adapt to different specifications of pipe in length and diameter. The machine can automatically unload the finished products, achieving full automation in pipe processing.

-

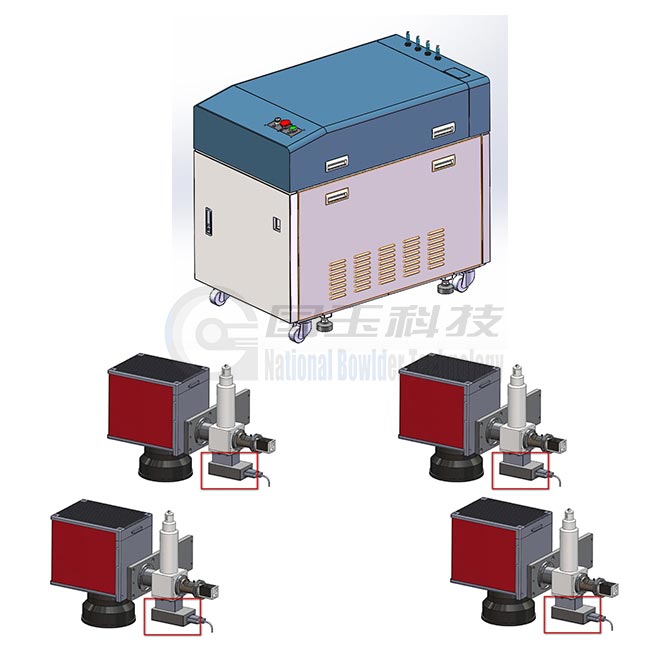

Laser cleaning device is going through a rapid development for the past few years. It’s originated from laser positive electrode correction device based on the working principle of material subtraction in means to refine chromatic aberration on the oxidized layer of the product surface. Using the high energy of laser, the stain on the oxidized surface will be evaporated instantly by laser to reach the cleaning effects.

-

This laser welding equipment is a portable laser welding equipment developed for welding surface that is not demanding. It can replace other manual welding methods such as electric welding. The power of the laser can be selected according to the needs of customers' products. Optional accessories like wire conveyor machine and different welding heads can also be selected according to the needs of welding.

related laser application

recommended machines

-

Laser Welding Machine with 4 Laser Outlets

Widely used on parts manufacturing with high precision, such as mobile phone, 3C electronics, computer accessories, battery ,communication device, hardware, etc.

-

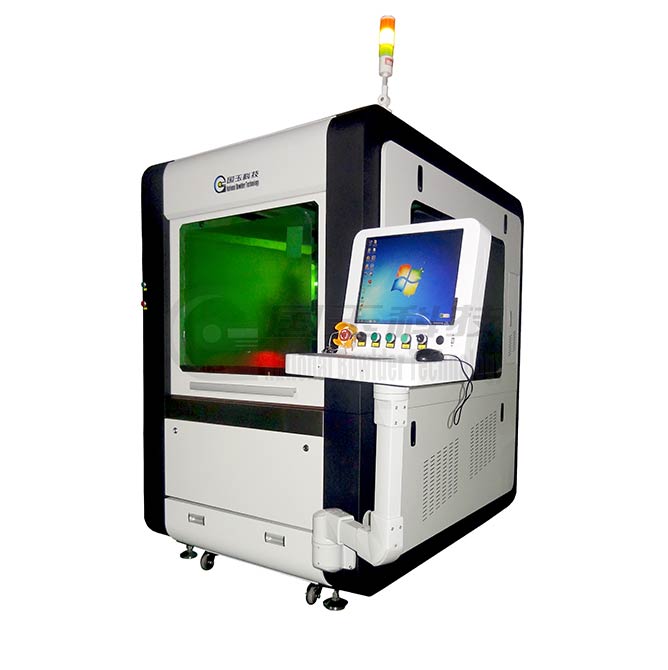

Ultra-high Precision Laser Intelligent Cutting Machine

Widely used in automobile manufacturing, metal plate processing, hardware manufacturing, kitchenware, advertising industry, elevator manufacturing, mold manufacturing, electronic components, mobile phone, 3C, aerospace, engineering machinery, petrochemical, new energy, food machinery, medical equipment And other industries.

-

Laser Cutting Machine for Irregular Pipes

It is widely used for pipes of various materials (such as electronic cigarettes), with neat and smooth cutting edges, no burrs, and extremely small burn edges. It is suitable for irregular pipe with high cutting edge requirements and high-precision cutting on product’s dimensions.