Proposals for the Current industrial development

The hardware machinery industry belongs to the traditional processing industry. First, the raw metal materials will be sorted before processing and then they will go through different working processes such as lathing, milling, planing, grinding, stamping, bending, etc., Finally they will be assembled into finished products. The processing technique of hardware component determines whether the hardware machinery enterprises can maintain the long-term operation and get more orders from the clients.

Analysis of the shortcomings of the hardware machinery industry:

1. The manufacturing process is complex. The hardware processing workflow has greater uncertainty. Meanwhile, there are many types of equipment and fixtures required for the production process. Therefore, the design and the management of the processing workflow are very difficult.

2. There are many types of finished products and semi-finished products. Generally, the typical production model for hardware is multiple batches and small volume, which is mostly customization. Therefore, the engineering requirements change frequently.

3. The education level and quality of employees in the hardware industry are generally lower than those in other industries. In addition, the degree of industrial automation and standardization is not high. Due to the high degree of human participation in the production process, operational errors often occur during processing, resulting in the decline of hardware’s quality during the processing and assembling.

The solution of laser automation in the hardware machinery industry

Nowadays, traditional machine cutting and argon arc welding cannot meet the requirements of modern hardware machining due to its poor processing accuracy and low efficiency. High-speed and high-precision laser automatic welding and cutting systems have emerged.

NBI has a good reputation in the domestic field of industrial laser automation. It has 20 years of experience and technical strength in the development of high-precision laser welding systems and high-speed laser cutting systems. It has successfully developed metal laser high-speed precision cutting system for many G500 companies such as the galvanometer laser welding system and other high-precision laser automation equipment.

industrial proposal with laser application

-

Faucets and showers have various shapes, square and round. The traditional welding process is prone to air holes, sand holes, water leakage and other defects, and they need to be polished after welding. The labor time cost is high, and the product consistency is poor. These problems are well solved by using laser welding stainless steel faucet and shower.

Laser welding non-contact processing does not need welding wire, which is easier to integrate automation. The surface of laser welded faucet and shower is smooth, and most of them do not need to be polished. -

Two directions for the development of kitchen ventilator: glass panel and all-stainless steel structure. Both directions involve the application of metal plate cutting. According to the size, physical feature and processing requirements of the incoming materials, NBI matches the appropriate laser cutting machine for the customer. The advantages of these laser cutting equipment are high cutting accuracy, less edge burn and chipping, small thermal deformation, and convenient for loading and unloading. In addition, automatic sample loading and unloading devices can be customized according to customer’s needs.

-

The traditional production workflow for water bottle starts with pipe marking from steel strap, next alloy steel blade cutting and cleaning. The disadvantage of this workflow is that more equipment for production are needed. Therefore, the power consumption is high, and more personnel are required for production. In contrast, the application of laser on pipe cutting greatly saves the cost for labor and power consumption. In addition, no extension nor cleansing for the finished piped are needed afterwards.

-

Ceramic substrate, good flatness, smooth surface, high temperature resistance, high pressure and high stability. It is a high-quality substrate for power circuits. In order to trace the production date, production line and other information of each circuit, it is necessary to mark the corresponding two-dimensional code on each ceramic substrate. The two-dimensional code printed by laser on the ceramic substrate can withstand the high temperature and corrosive solution cleaning in the later circuit manufacturing process without discoloration and falling off.

related laser application

recommended machines

-

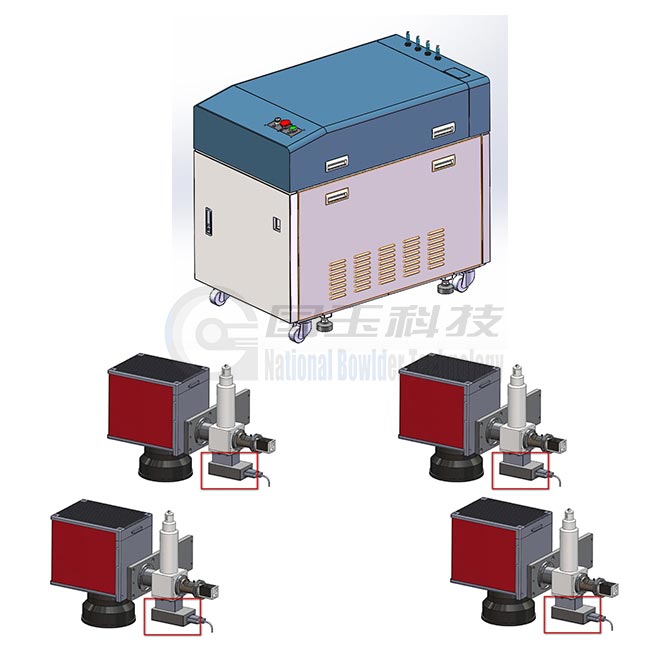

Laser Welding Machine with 4 Laser Outlets

Widely used on parts manufacturing with high precision, such as mobile phone, 3C electronics, computer accessories, battery ,communication device, hardware, etc.

-

Marking Machine with automatic Sample Loading and Unloading Function

This machine can be extensively applied on the ceramic plate, metal plate, sheet glass and other sheet form material for coding, testing, surface repairing, etc. The machine can automatically load and unload the samples so no damage or scratch can be caused on the surface of the products.

-

Continuous Laser Cutting Machine for Pipes

It can automatically connect to the pipe making machine and adapt to a wide range of pipes’ cutting. Simply adjust the time period when changing products. It can not only automatically load and unload the pipes, but also seamlessly connect with the original production line, which is widely used in the online dynamic rotational cutting of various stainless-steel pipes.