Proposals for the Current industrial development

On February 5, 2021, the National Medical Machinery Supervision and Management Work Conference was held in Beijing. The meeting was guided by Xi Jinping’s Thought on Socialism with Chinese Characteristics for the New Era, implemented the decisions and arrangements of the Central Economic Work Conference. The meeting clearly pointed out that we must do our best to monitor the quality of medical equipment for epidemic prevention and control; meanwhile, to supervise enterprises to fulfill their main responsibilities; to strengthen supervision and inspection on the quality of export product, effectively guarantee the safety use and effectiveness of the equipment to promote the high-quality development of the medical equipment industry.

Medical equipment is high value product with strict quality requirements and extremely harsh manufacturing processes. Therefore, technologies such as high-precision laser welding, ultra-fast laser cutting and laser marking is getting more attention in the field of medical equipment and have been widely used.

In medical equipment processing applications, traditional processing methods, such as plasma spraying, sintering, electrochemical deposition, etc., are no longer suitable for the processing of biomaterial medical equipment due to the high temperature, high acid, and high alkali processing environment. In contrast, ultrashort pulse laser micromachining has the advantages of low energy consumption, low damage, high accuracy, precise positioning in 3D space, etc. Meanwhile, it can also be processed in the cold environment, which has a good application prospect in medical equipment processing.

industrial proposal with laser application

-

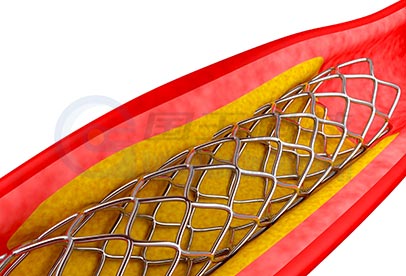

Stent, also known as coronary stent, is a commonly used medical device in interventional heart surgery and has the function of dredging arteries and blood vessels. The main material is stainless steel, nickel-titanium alloy or cobalt-chromium alloy. In the 1980s, metal stents, drug-coated stents, and bioabsorbable stents were successfully developed. At present, the processing of stents is mainly done by precision laser cutting. The stent laser cutting machine, large stent laser cutting machine, and stent femtosecond laser cutting machine developed by NBI can meet the needs of different types of stent processing.

-

The development of medical equipment has created a huge demand for laser plastic welding. After years of processing technique development, NBI has filed a number of patented products for the direct welding of different plastic materials; they are widely used in the production process of medical equipment. According to different plastic types and properties, NBI pairs suitable light sources, external light paths and molds to provide suggestions for improving processing technique and proposals for plastic laryngoscope welding with strong custom development capabilities.

-

Laser marking is used to replace the original coding & marking method. Because medical equipment and medical auxiliary products directly apply on the human body, the European Union took the lead in eliminating the use of ink on such items. The laser marking system developed by NBI can be flexibly applied on to the production line of various products, and can be connected to the enterprise's MES management system as joint modules to achieve the purpose of production traceability, production status control, and after-sale traceability.

related laser application

recommended machines

-

High Precision Continuous Fiber Laser Cutting Machine

Widely used in automobile manufacturing, sheet metal processing, hardware manufacturing, kitchenware industry, advertising industry, elevator manufacturing, mold manufacturing, electronic components, 3C, aerospace, engineering machinery, petrochemical, new energy, food machinery, medical equipment, etc.

-

Laser Welding Machine for Medical Plastic Laryngoscope

Widely used in the welding of plastic laryngoscope in the medical industry.

-

High Precision Pipe Laser Cutting Machine

It is widely used in the medical industry for high precision cutting