Proposals for the Current industrial development

The global energy crisis and environmental pollution problems are becoming increasingly prominent. The development of industries with energy conservation and environmental protection is highly valued. The concept of new energy has emerged along with the trend. New energy has been continuously applied to various industries. The use of new energy in the automotive sector, which consumes the most fuel, has become increasingly prominent. Automobile companies continue to increase their investment in research and development of new energy vehicles. The research and development of the new energy vehicle comes with fruitful results. Many new energy vehicles and buses have been applied to daily life. Batteries with high-capacity (lithium batteries, nickel-hydrogen batteries, hydrogen batteries) are the most important components of new energy vehicles. In order to ensure the stability and sustainability new energy batteries, laser welding has become an inevitable choice in the manufacture process of batteries.

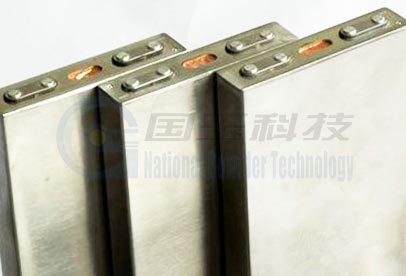

Today’s new energy vehicles have achieved 100 kilometers acceleration in just a few seconds, allowing more people to feel the passion of driving “supercars”. And the speed of the new energy vehicles is driven by hundreds of lithium battery Cell modules. In the manufacturing process of lithium batteries and battery packs, Welding is needed in more than 20 working processes to realize the interconnection or packaging of battery modules. Therefore, the welding quality plays a very important role in the safety of the vehicle.

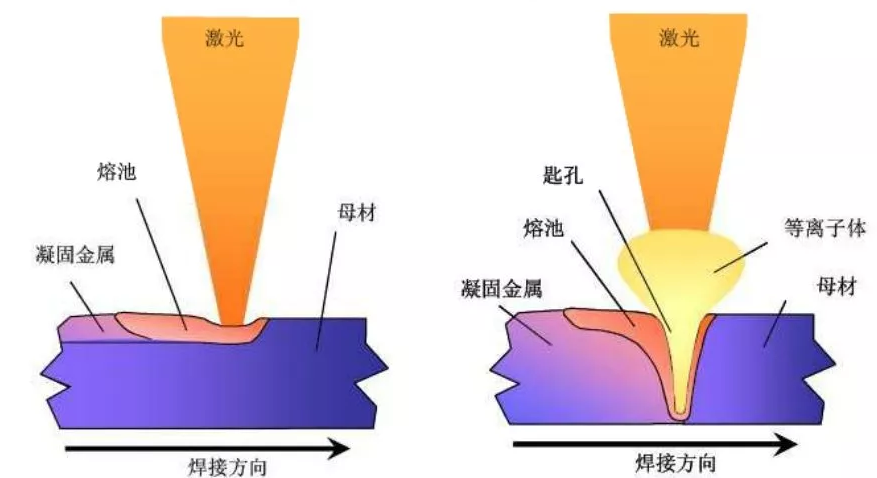

Laser welding is an advanced non-contact welding method that combines the atoms of two separated products by focusing a high-energy laser beam on the surface or inside of the workpiece. Compared with traditional argon arc welding, resistance welding, and ultrasonic welding, laser welding has three main advantages:

1. The heat affected zone is small;

2. Non-contact processing;

3. High welding efficiency;

In the field of new energy batteries, as a manufacturer of high-precision laser automation equipment, NBI’s battery laser welding system has been purchased by many well-known battery manufacturers. It is widely used in the manufacture of tabs, battery cell shells, sealing nails, flex connections, and explosion-proof valves, etc.

industrial proposal with laser application

-

As a primary energy, hydrogen fuel cell is another important support for the development of battery in China. Now there are two main routes; One is graphite bipolar plate and the other is metal bipolar plate. The welding requirements of different routes are also inconsistent; The production process of graphite bipolar plate does not need laser sealing welding, and metal bipolar plate needs laser sealing welding. The reactor production in both routes can adopt the reactor automatic strap welding machine developed by Guoyu Technology (the equipment integrates automatic strap feeding, automatic pressing according to different cell thickness, automatic welding after strap adjustment, and entering the next section of the assembly line after welding).

-

In the production process of lithium battery, laser processing technology is an essential processing means. Whether cylindrical, square or current blade batteries, laser processing equipment runs through the whole production process. Cutting of battery pole piece, laser cleaning of battery shell, welding of electrode, external welding of pole piece, sealing welding, explosion-proof port welding and liquid injection port welding. The above is the demand for laser equipment in the production of cell, and the demand for module production in the later stage: laser cleaning, laser coding, pole piece welding, pole column welding and shell sealing welding. Now the production technology of lithium battery has matured and is rapidly mass produced. Guoyu technology has a full set of laser processing technology.

-

No matter what kind of battery production process, testing equipment is essential. Guoyu technology is engaged in air tightness test, appearance dimension test and height test of bipolar sheet sealant.

related laser application

recommended machines

-

Hydrogen Battery Laser Welding Machine

Widely used in different types of hydrogen fuel battery strap welding and BPP welding

-

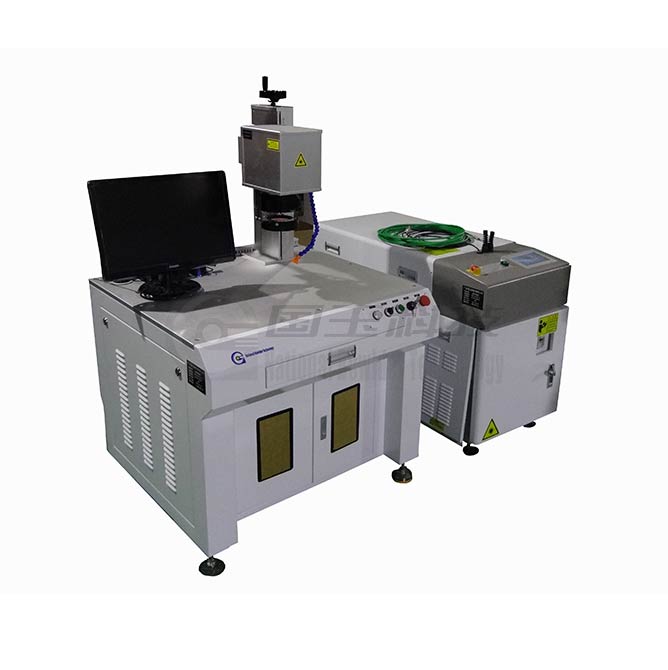

Galvanometer Laser Welding Machine

Widely used in different industries such as 3C, cell phone module manufacture, computer accessories, automobile accessories, lithium battery, medical equipment, mini motor, home appliance switch, kitchen and sanitary products, cookware, and stainless-steel manufacturing, etc.

-

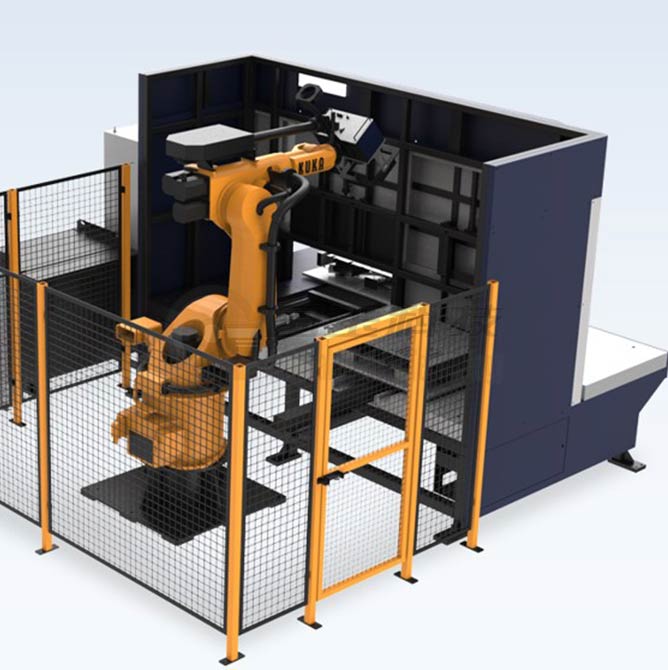

Automatic Laser Welding Machine with Robot Arm

Widely used in the automotive industry, sheet metal processing, mold manufacturing, electronic engineering, aerospace, engineering machinery, petrochemical, energy, nuclear power, rail transit, shipbuilding, mining, metallurgical equipment, food machinery, medical equipment and other industries.Widely used in the automotive industry, sheet metal processing, mold manufacturing, electronic engineering, aerospace, engineering machinery, petrochemical, energy, nuclear power, rail transit, shipbuilding, mining, metallurgical equipment, food machinery, medical equipment and other industries.