Proposals for the Current industrial development

he safety of daily necessities and food is closely related to people’s lives. The packaging of these products is very important as it reflects the unique characteristic of the product and displays product information.

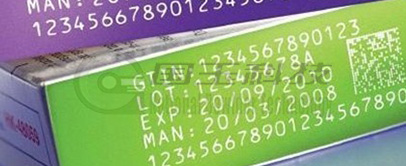

In order to prevent competitor counterfeiting and be able to scientifically manage sales in different regions, manufacturers use high-tech anti-counterfeiting methods to mark their products. Some manufacturers mark their products with traceability QR codes so that they can inquire and track the information from the beginning of the manufacturing process to the market circulation. The establishment of the traceability system helps to ensure the safety of products and meanwhile, improve the production efficiency and profitability of enterprises, and combat counterfeit and shoddy products.

industrial proposal with laser application

-

The laser marking machine developed by NBI circumvents the shortcomings of traditional inkjet printers. It has many advantages such as permanently marked and coded information, environmental friendly ad high efficient device. With high efficiency, high quality and accurate marking results, product traceability systems can be easily built.

The laser marking technology developed by NBI breaks through the standardization and singularity of traditional inkjet coding technology, which creates a new marking method that highlights product characteristics and differences in means to provides flexibility to shorten the product upgrade circulation.

-

Due to food safety concerns, inkjet printing method is slowly withdrawing from history and replacing with laser coding, which is not easy to remove. Its processing speed is faster. It’s compatible with different materials and produces less waste material, which makes it more and more outstanding in the market. Targeting at the high-end packaging industry, NBI has developed a special laser equipment for glass coding with exquisite look, small size, ergonomic design, high reliability, and more cost-effective.

-

In order to promote sales, many merchants will add winning information on their products. In the past, they used ink printing methods inside the products, but now that everyone is getting more concerned about food safety, which is why laser coding equipment for bottle caps has been born. The double-headed laser marking machine can mark on the white cap with 34-bit data of 12*12 2D code developed by NBI, which can achieve stable production of 1000 per minute.

related laser application

recommended machines

-

Intelligent Laser Tap Remover and Optical Package Sorting Machine

Widely used on the carton box, shielding bags, sample plate and other external package’s code and tap removal.

-

High-Speed Laser Marking System

It is widely used in the production lines of tobacco, wine, mineral water, catering seasonings, wire and cable, plastic pipes, integrated circuit chips, computer accessories, communication products, hardware products, battery electronics and other industries that require high-speed marking.

-

Marking Machine with automatic Sample Loading and Unloading Function

This machine can be extensively applied on the ceramic plate, metal plate, sheet glass and other sheet form material for coding, testing, surface repairing, etc. The machine can automatically load and unload the samples so no damage or scratch can be caused on the surface of the products.