Proposals for the Current industrial development

With the rapid development of the 3C electronics industry, 3C electronic products are being upgraded towards high integration and ultra-high precision. The components in the products are getting more and more refined, and the requirements for precision and electronic integration are higher. Therefore, the welding requirements for the shape, deformation and tensility of the inner structure are more demanding than before. Laser products are widely used for frame welding, precision cutting and traceability marking in 3C products manufacture for their high energy, high precision, high directionality and flexibility. At present, in the production process of high-end electronic equipment, the application of laser technology has played an important role in improving the quality of products, making the products more refined, more portable, and more robust.

We can find the application of laser on most of the 3C electronic products on the market today. As a pioneer in the laser industry, NBI Technology is committed to providing various types of industrial laser automation equipment for the 3C electronics industry with complete industrial automation solutions.

Laser automation equipment such as laser welding machines can be applied on consumer electronics products; laser cutting machine for VR polarized film cutting and optical glass cutting; laser marking can be seen on electronic component for visual marking and body marking, all of which have helped solve the problems in the manufacturing process in the 3C electronics industry.

NBI Technology’s industrial laser automation equipment has been widely used in many manufacturing fields in the 3C electronics industry. As one of the leading company in the industry, NBI is committed to providing customers with the best and the most complete and up today industrial solutions.

industrial proposal with laser application

-

With the market demand and the continuous upgrading of consumer electronic products, membrane materials and ultra-thin glass are more and more widely used, and the market share is also expanding. Consumer electronic products (such as smart phones, wearable products, VR and AR glasses and other virtual application products) have higher and higher requirements for film materials and ultra-thin glass. With extremely high edge requirements and optical angle requirements, as well as a variety of product shapes, laser has great advantages in composite cutting, so this kind of special laser cutting equipment came into being.

-

The dissimilar material laser welding machine developed by NBI is welding machine with high-performance and precision. It not only fulfills the welding needs and requirements for different high-reflection thin-walled materials but also more cost effective. It adopts customized light source, galvanometer system with high stability, CCD positioning system with high-precision and power monitoring system, specifically customized for the welding of different thin materials with high-reflection.

-

The laser cutting equipment developed by NBI is suitable for laser cutting of various brittle materials, and different cutting methods are used for processing according to its light transmittance. The total cutting process is divided into two: direct cutting and detachment. Using Laser to cut brittle material effectively minimizes the amounts of chipping, which can be controlled between 50um-8um according to the materials and their thickness.

-

Ultra-fast laser marking uses the characteristics of peak power of the laser to process materials. Since the time of a pulse is in picoseconds or femtoseconds, this laser has ultra-high peak power (it can make the processed part of the material vaporize and instantaneously). It is like a fast, fine and unbreakable tool, which can process very fine patterns; and products with very high requirements for processing heat.

related laser application

recommended machines

-

Marking Machine with automatic Sample Loading and Unloading Function

This machine can be extensively applied on the ceramic plate, metal plate, sheet glass and other sheet form material for coding, testing, surface repairing, etc. The machine can automatically load and unload the samples so no damage or scratch can be caused on the surface of the products.

-

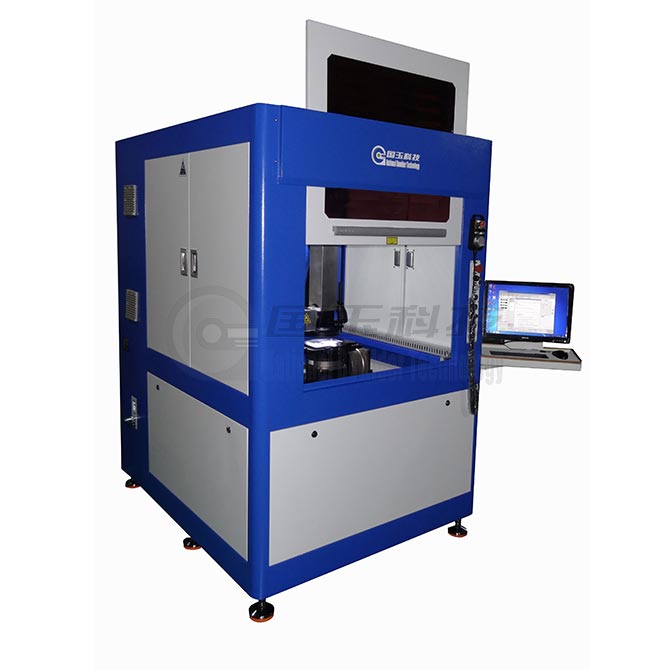

Laser Precision Cutting Machine for Non- metallic Material

This machine can be extensively applied on glass, polarized film, protective film, electromagnet film and cover film cutting. The cutting edge is smooth and neat, no chipping nor excessive glue, melting edge is relatively small. The edge quality is stable. Less waste material and high efficient in the cutting process. It’s suitable for products with high requirements on cutting edge quality and high precision on cutting dimension.

-

Intellectual Visual Inspection Device

The visual system developed by NBI can automatically classify the grey level and size of different stains on the surface of the product; It uses the algorithm to divide different types of doping based on different laser processing parameters, thereby blackening the stains to be consistent with the surrounding background color, The chromatic aberration is difficult for the human eye to detect. That is why the repair of anode defects is needed and widely used in the three-dimensional surface inspection and repair of the shells of smart phones, notebooks, tablets, and wearable products.