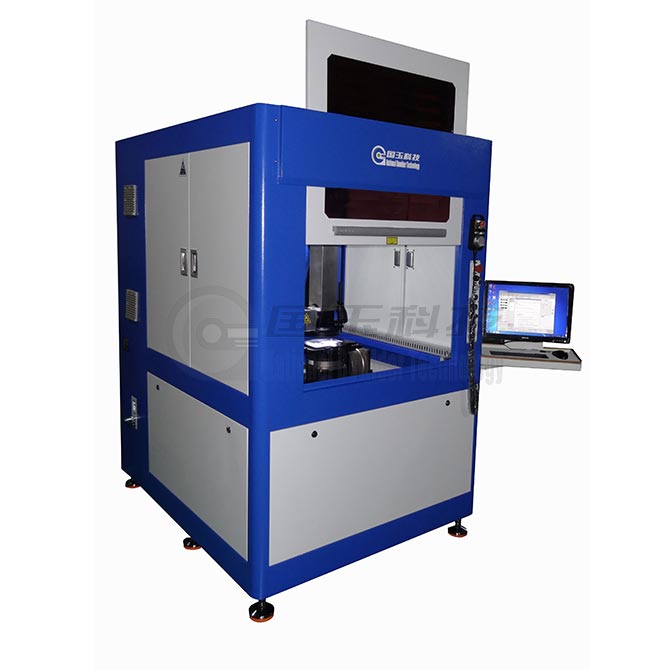

Intellectual Visual Inspection Device

Free Proofing

The visual system developed by NBI can automatically classify the grey level and size of different stains on the surface of the product; It uses the algorithm to divide different types of doping based on different laser processing parameters, thereby blackening the stains to be consistent with the surrounding background color, The chromatic aberration is difficult for the human eye to detect. That is why the repair of anode defects is needed and widely used in the three-dimensional surface inspection and repair of the shells of smart phones, notebooks, tablets, and wearable products.

-

Applicable Product

The visual system developed by NBI can automatically classify the grey level and size of different stains on the surface of the product; It uses the algorithm to divide different types of doping based on different laser processing parameters, thereby blackening the stains to be consistent with the surrounding background color, The chromatic aberration is difficult for the human eye to detect. That is why the repair of anode defects is needed and widely used in the three-dimensional surface inspection and repair of the shells of smart phones, notebooks, tablets, and wearable products.

Standard Functions

5 axis-moving platform, visual recognition system, laser system, ventilation system

Optional Functions

Optical surface effects, image capture and auto save, product statistical analysis, MES access modules.

Technical Parameters

overall dimension 1250mm*1600mm*1950mm weight 1500KG moving platform X-Y-Z-R1-R2 5 axis platform (reposition accuracy±0.02 mm) power supply AC220 / 4.5KW laser type Optical Fiber Laser power 20 W (optional) working range 400*300 mm (based on the actual situation)