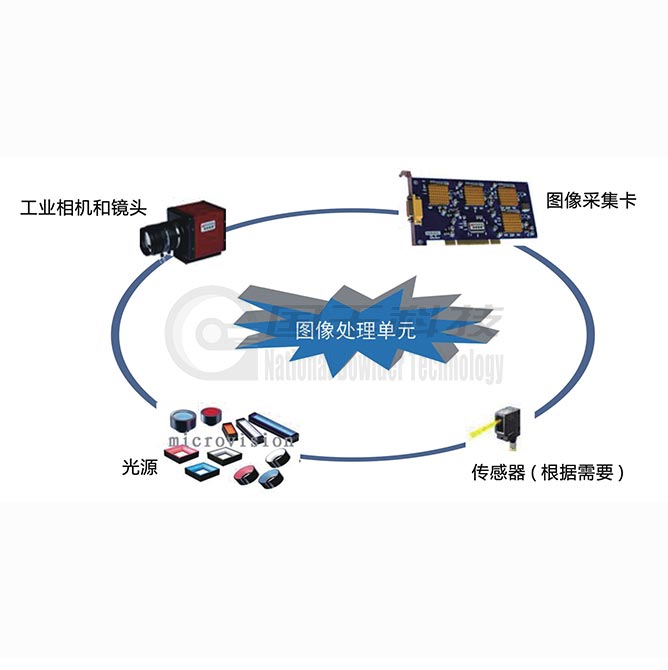

Visual Inspection System

Free Proofing

Support different camera’s brand, multiple tasks parallel running, hundreds of algorithm, secondary development and communication mode TCP/IP、RS232、I/O.

-

Technical Support

Support different camera's brand, multiple tasks parallel running, hundreds of algorithm, secondary development and communication mode TCP/IP、RS232、I/O.

Standard Functions

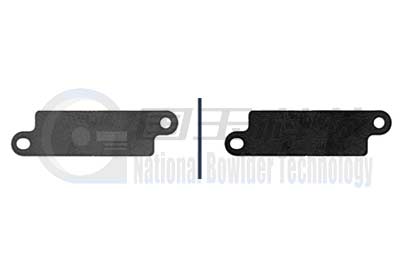

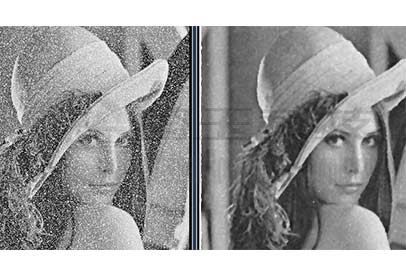

Composed of nearly a thousand self-developed image processing algorithms and a variety of interactive tools, it can meet the needs of positioning, measurement, identification and detection in different visual applications.

Optional Functions

Professional customers can develop customized algorithm according to their own needs and the given interface. They can also customized different functions for motion control support, marking support.

Technical Parameters

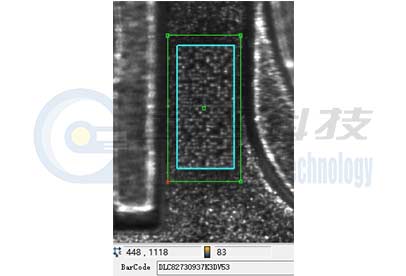

image acquisition tools Select image from local cameras (support the mainstream cameras, AVT/PointGrey/The Imaging Source/Daheng Image/Hikvision/Dahua,etc), local image Marking tools N-point marking, Box marking, graphic aberration correction pre-processing tools threshold offset, image enhancement, ROI setting, RGB to grey-scale map image filtering, morphological shifting. system tools fonts display, image record, image acquisition, image saving, presentation, customized script. positioning tools shape paring, grey scale paring, integrated shape paring, welding spot searching measurement tools search for circle, straight line, calipers mathematical tools data analysis, lines relations, point to line distance, line to line distance , point to point distance, coordinate shifting communication tools data sending and receiving ,Modbus sending and Modbus reading, input and output. Identification tools script identification, bar code and QR code identification logical tools define variables, variables setting, loop control, condition control Feature inspection scratch detection, flaw detection, pit detection, edge inspection, hump detection, quantity detection, gray scale analysis, symmetry properties judge, area inspection, blob analysis. marking control standard marking motion control axis motion, axial coordinate acquisition, motion adding