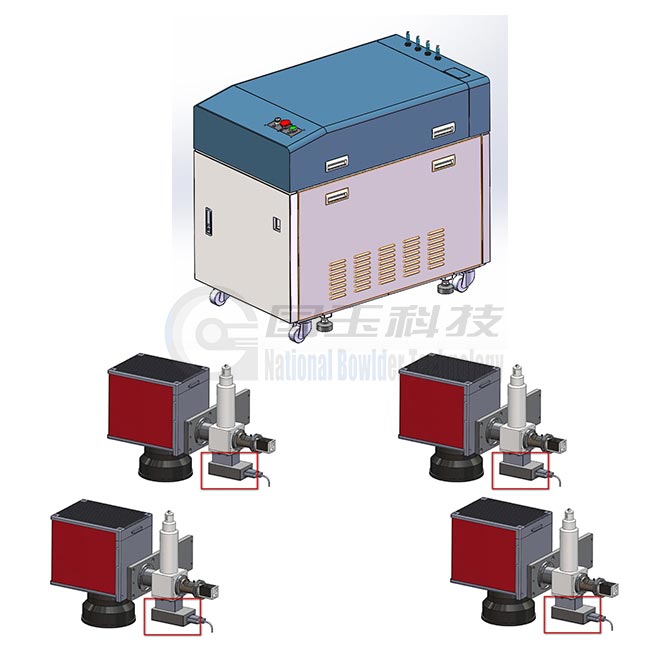

Laser Welding Machine with 4 Laser Outlets

Free Proofing

Widely used on parts manufacturing with high precision, such as mobile phone, 3C electronics, computer accessories, battery ,communication device, hardware, etc.

-

Applicable Product

Widely used on parts manufacturing with high precision, such as mobile phone, 3C electronics, computer accessories, battery ,communication device, hardware, etc.

Equipment Introduction

The equipment can realize splicing welding, stitch welding of the same metal or different metal materials. This laser device is integrated with high-performance beam splitting control system, which can control beam splitting mode in terms of time and energy. (PS: Energy beam splitting mode: Beam can be split via multiple welding outlets at the same time; Time splitting mode, using multiple optical fibers with multiple welding outlets line up for welding but only one welding head can emit the laser beam) It also adopts multi-workstation processing by splitting multiple beams via 4 welding outlets at the same time to achieve more precise welding. This laser welding machine is characterized by its thin welding seam, large depth, small taper, high precision, beautiful welding seam, no deformation of the product after welding, and offline/online welding control for mass production.

Technical Parameters

laser type optical fiber wavelength 1064nm output power 150W beam splitting mode high speed time splitting mode pulse width 0.1-20ns pulse repeating frequency 1-200HZ loop feedback control mode Random wave Realtime power control feedback energy fluctuation < ±3% numbers of outlets for light splitting ≤4 (standard 1 beam outlet,optional 4 outlets) cooling system Air cooling power consumption 8-12KW required power supply AC380V±10% 50/60Hz